01

UNIVERSE |

01

Best performance in the cases:

|

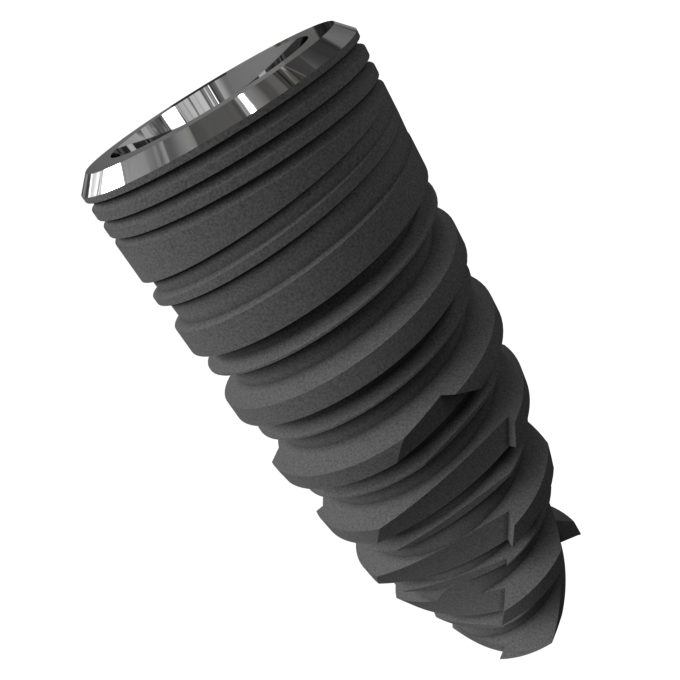

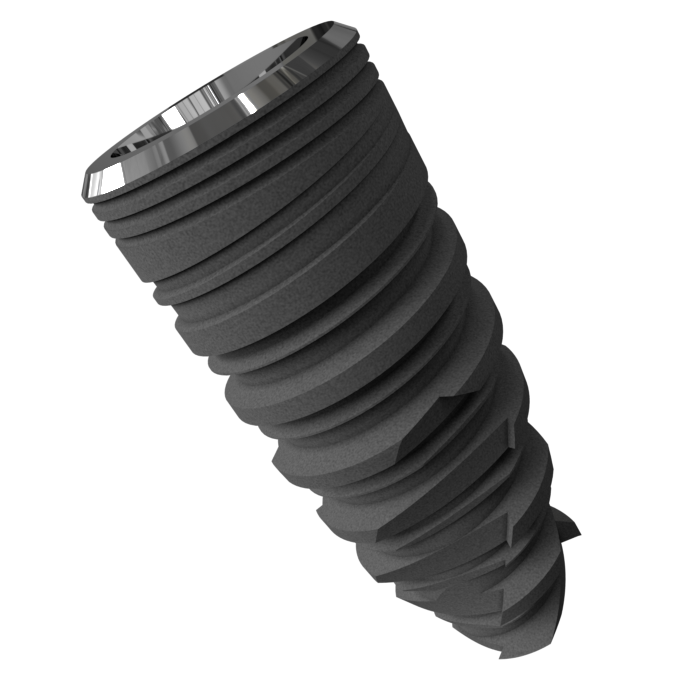

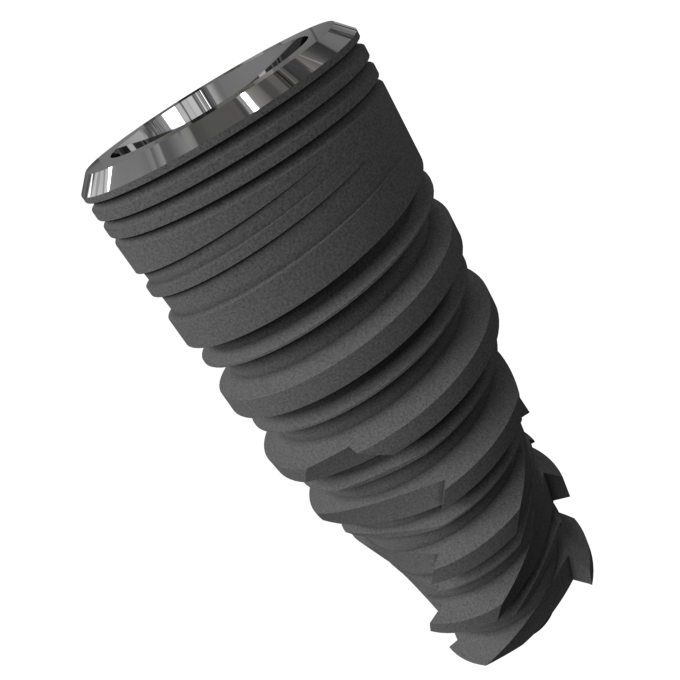

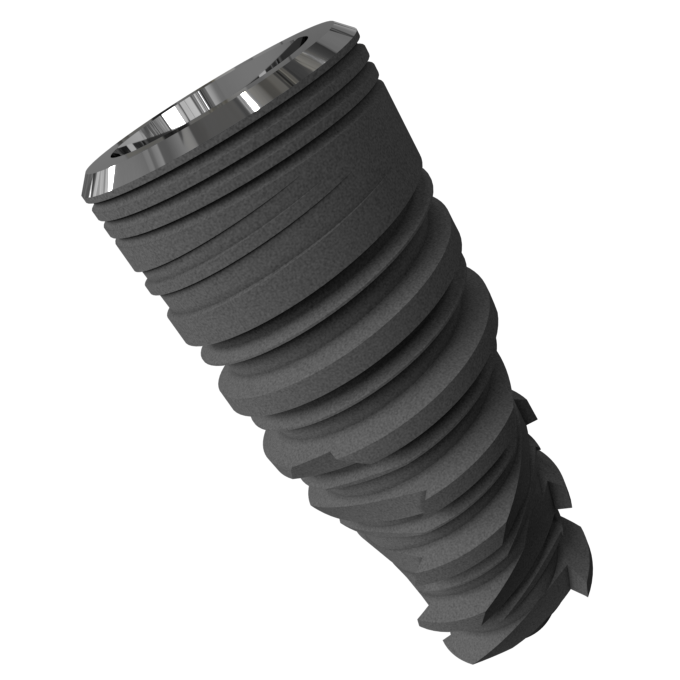

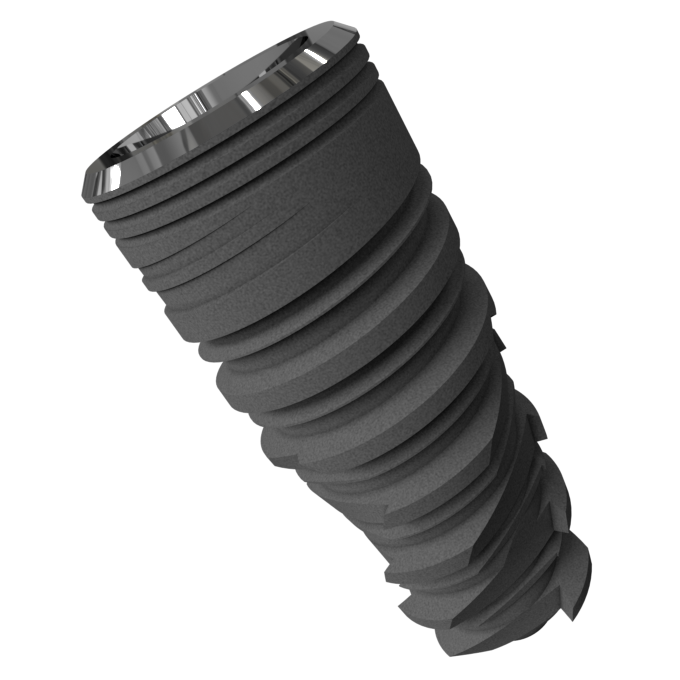

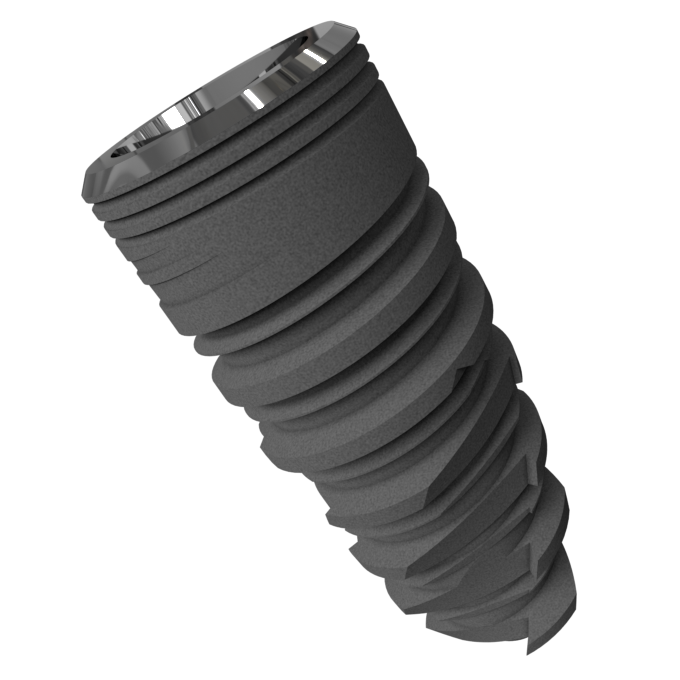

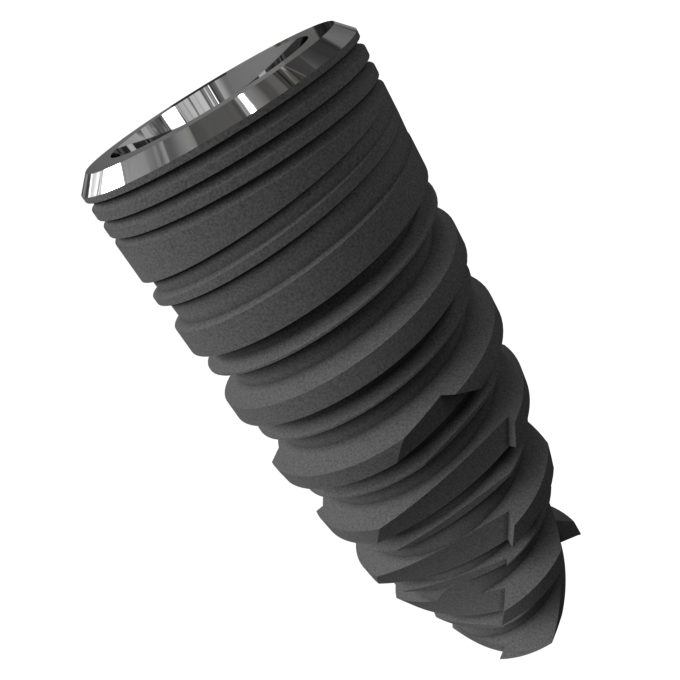

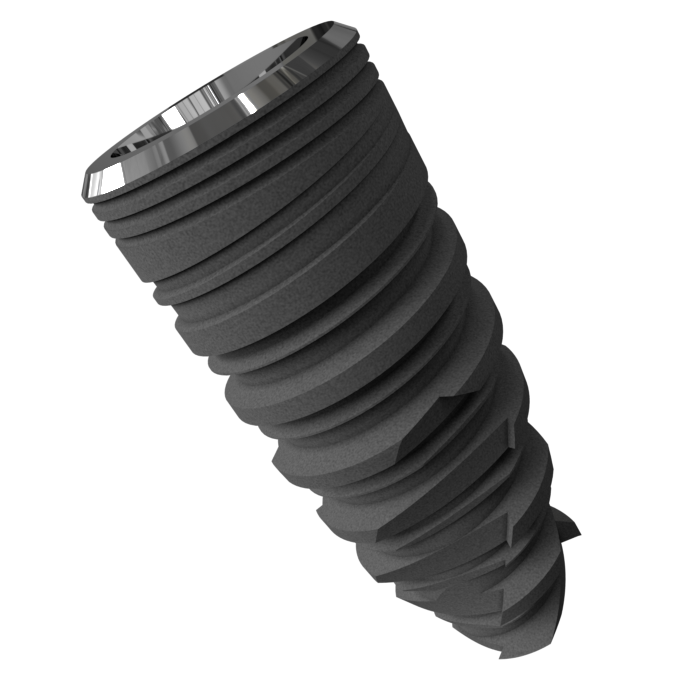

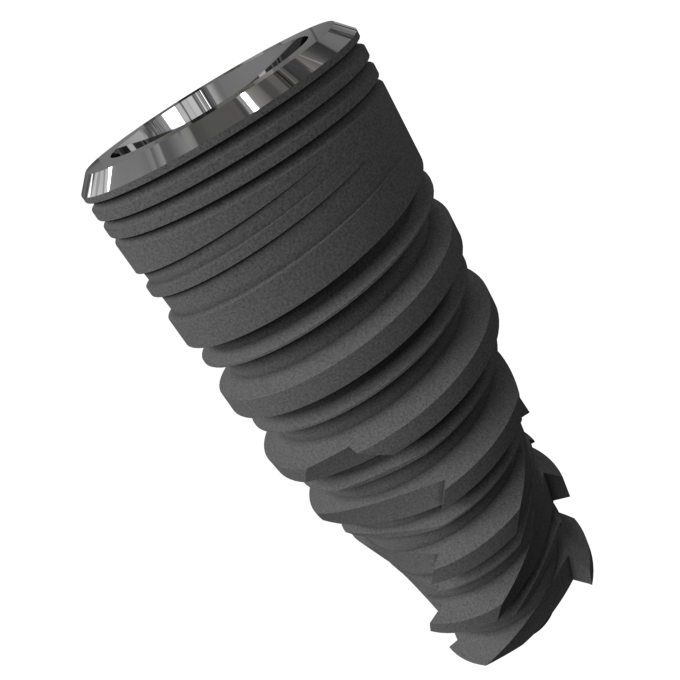

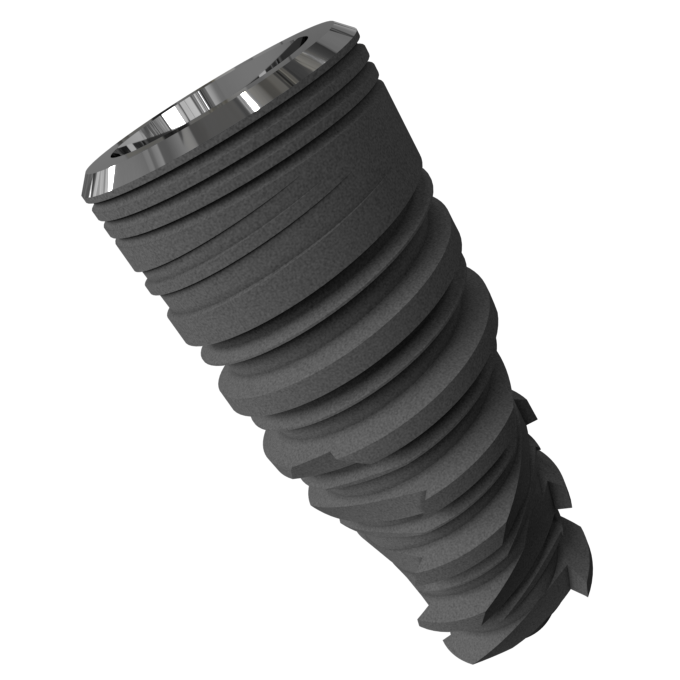

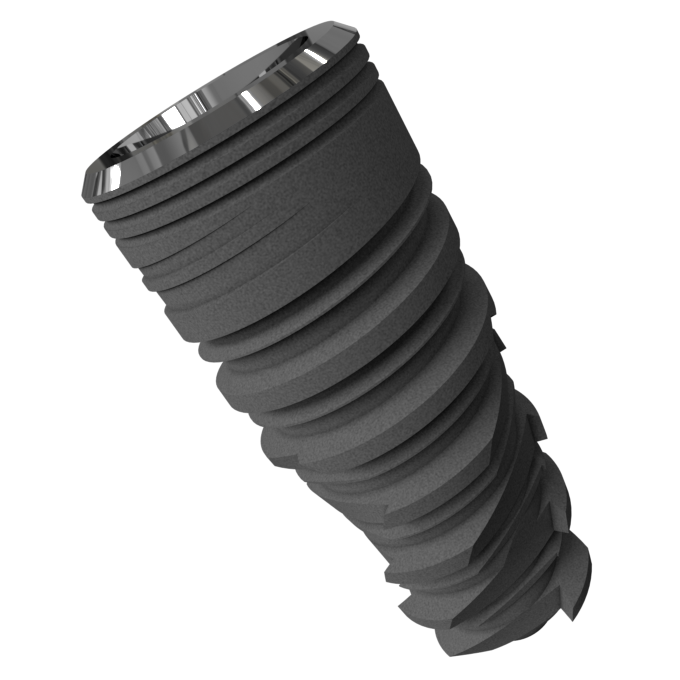

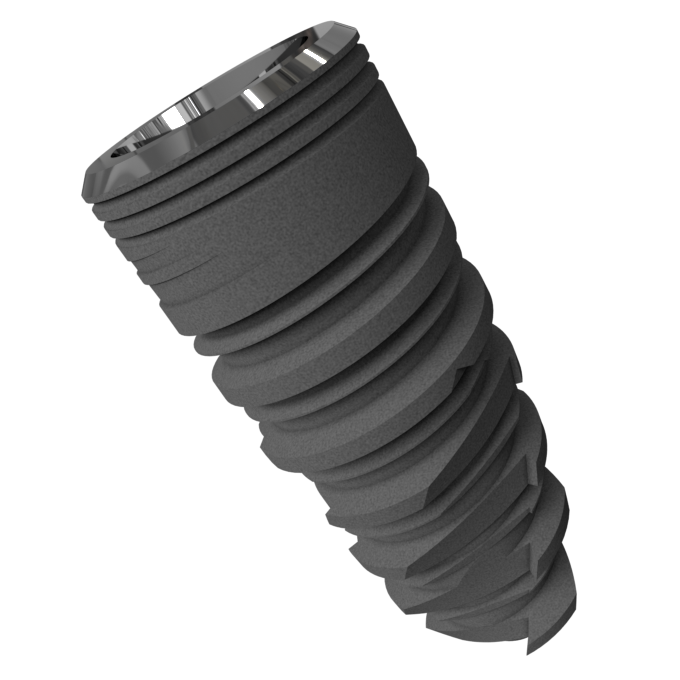

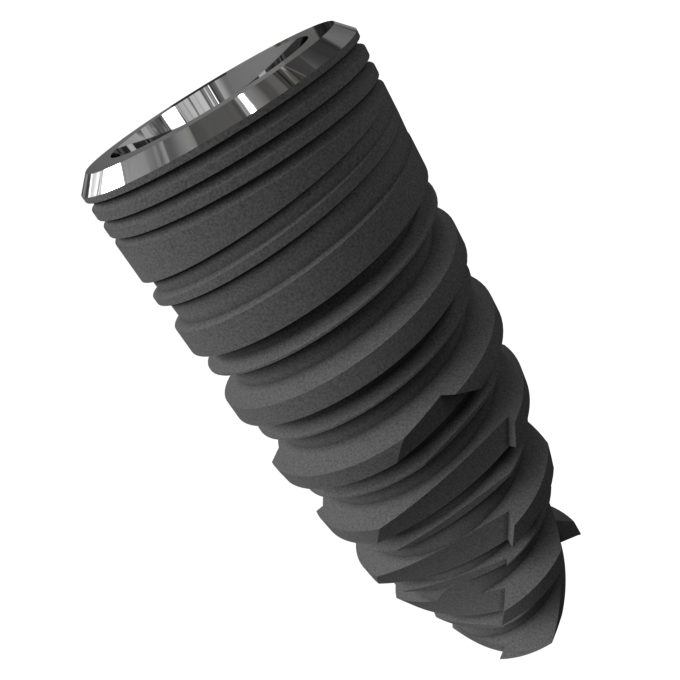

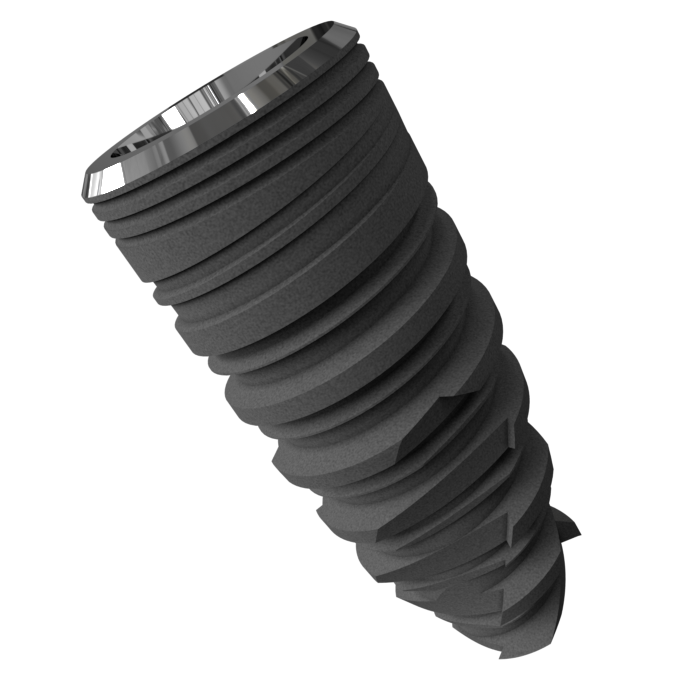

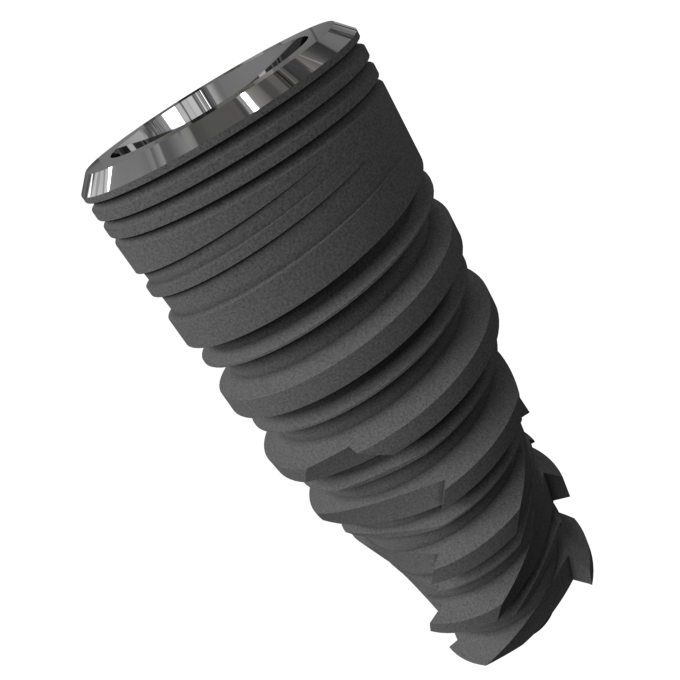

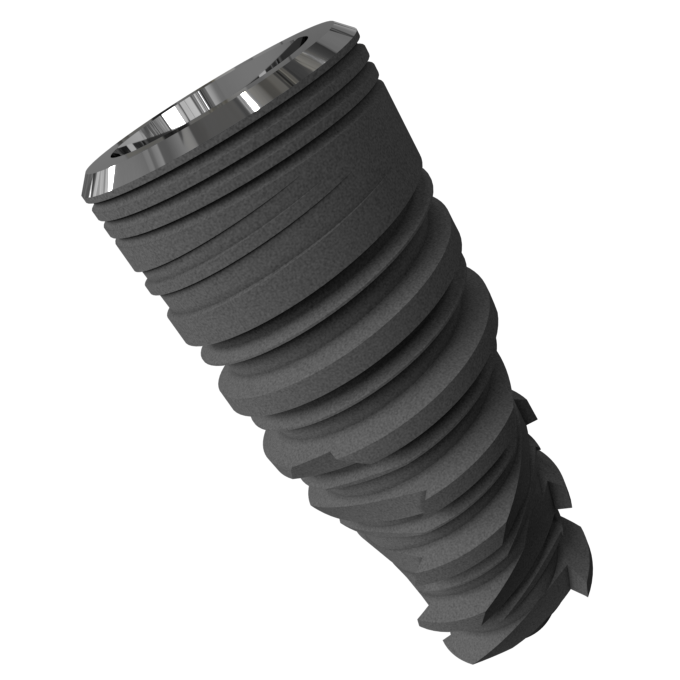

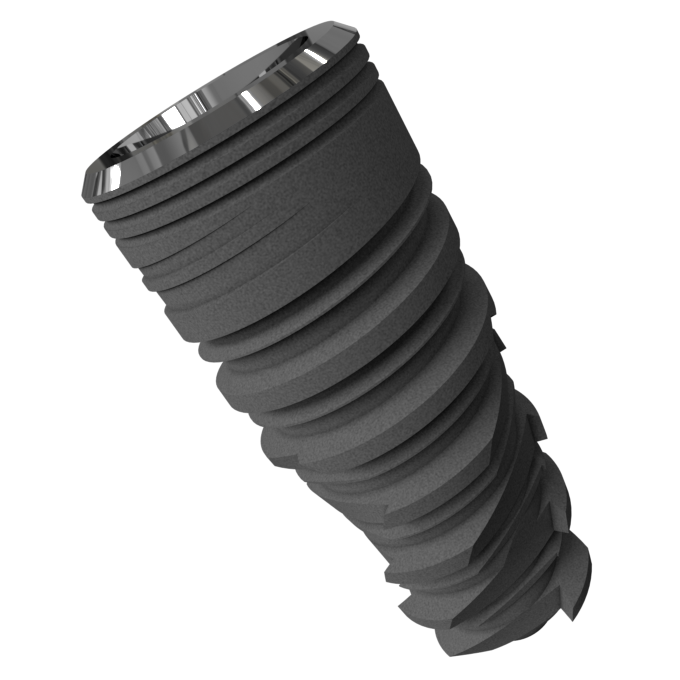

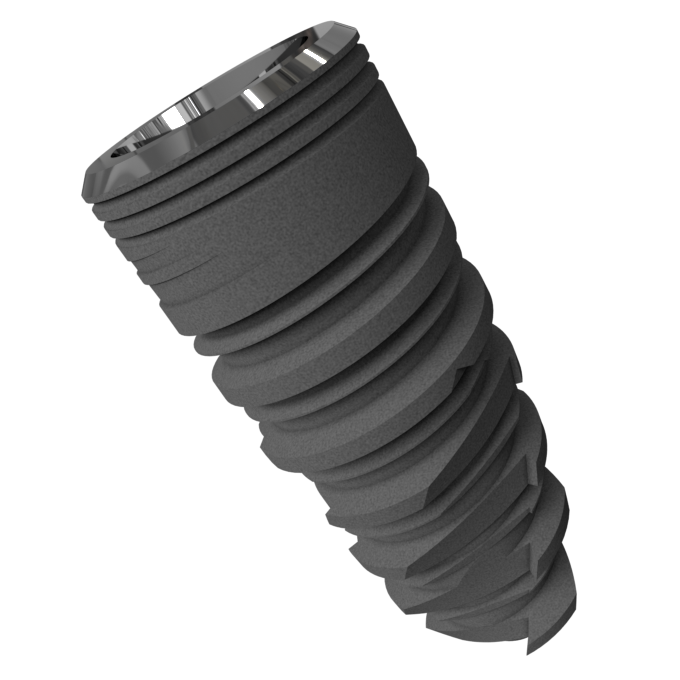

Universe, with its particular conical shape, offers significant benefits for a wide spectrum of clinical applications providing excellent aesthetic results.

The implant features a highly innovative thread design.

This special morphology, due to the combination to the spiral squared and spiral buttress threads, is able to increase the implant surface by 20% compared to the same implant without buttress threads providing a greater and more uniform area of contact between bone and implant speeding up the osteointegration process.

The alternate buttress and square double spiral loop generates a perfect balance between intrusive, compressive, and diverging forces capable of providing the bone with exceptional growth stimuli.

The strong threads are designed for the added compression and surface area required in soft bone placement in order to fill void spaces around the threads by ensuring an immediate primary stability.

Indeed, Universe, shows exceptional self-drilling properties which facilitate the implant placement and redirection in D1 and D2 bone types.

Universe stands out also for its excellent apical part design self-drilling and self-tapping.

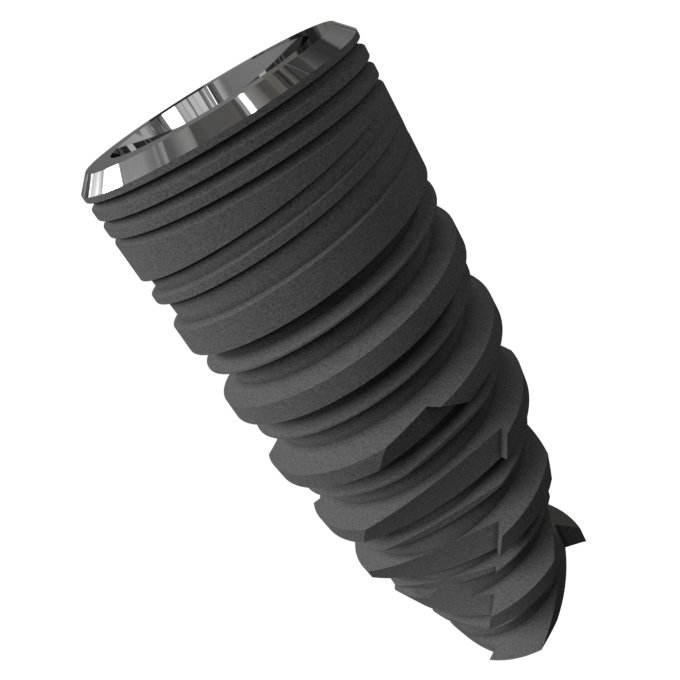

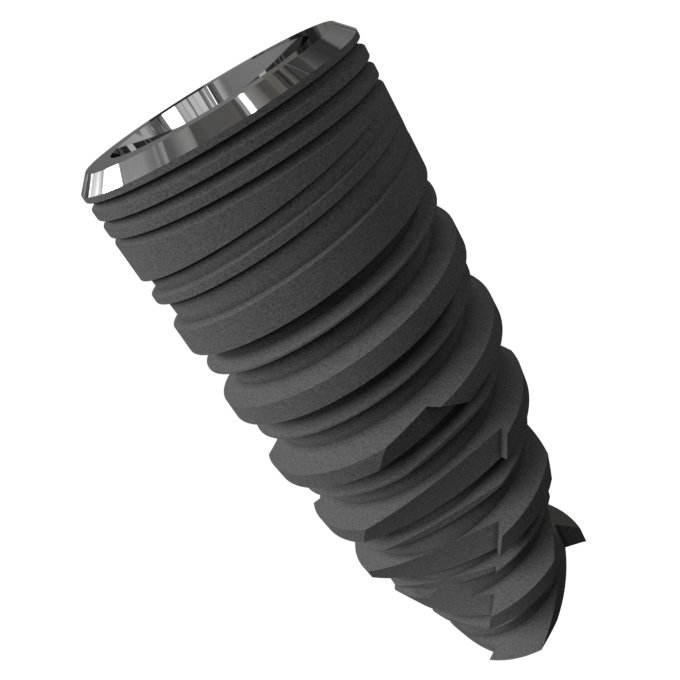

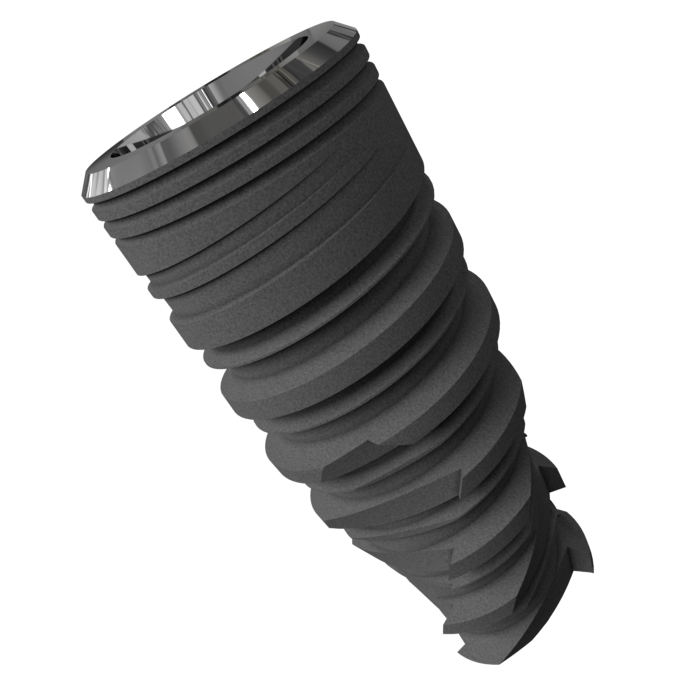

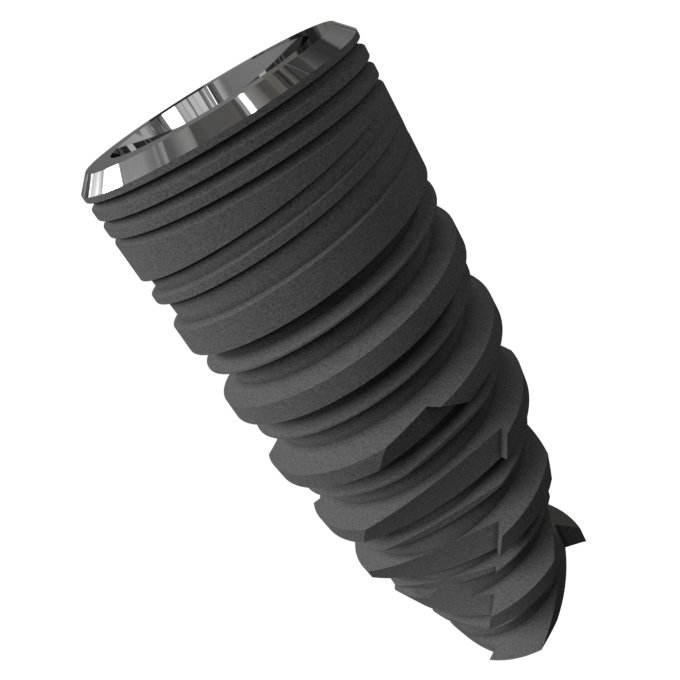

A true “cold welding” in the taper Implant-abutment connection is produced by contact pressure between the surface of the female cone of the implant and that of the male cone of the abutment.

The friction created between the two surfaces of equal conicity tightened to 35 Ncm generates direct, durable, and waterproof interlocking. In fact, this type of connection is the only one that approaches the ideal condition of a one-piece implant, which is the one used in the monophasic system, universally proven to be longer-lasting than biphasic systems.

However, being able to mechanically achieve a perfect Morse tapered connection requires great attention and special skills starting from the design stage.

IML’s designers and mechanics know how to detect and evaluate each critical point in order to produce perfect components whose connection not only works well during the project but especially

also in the patient’s mouth throughout their life.

As demonstrated by numerous studies carried out around the world, the resulting system is effective and reliable.The Universe implant has the advantage of a locking taper connection with a passing screw which achieves a precise and functionally perfect fit when coupled with a double internal hexagon. A design choice facilitating procedures during the surgical phase.

The decisive factor in achieving complete system stability is to determine the function of the passing screw, which must guarantee the implant-abutment connection. This work is not easy as the screw is repeatedly subject to vibration fatigue which naturally tends to cause the unscrewing of the screw

from its seat.

Here the solution identified by IML is the taper connection of the screw head inside the abutment.

The Universe implant connection is not only designed to guarantee correct implementation of the benefits of a locking taper connection but also those of a “one piece” implant.

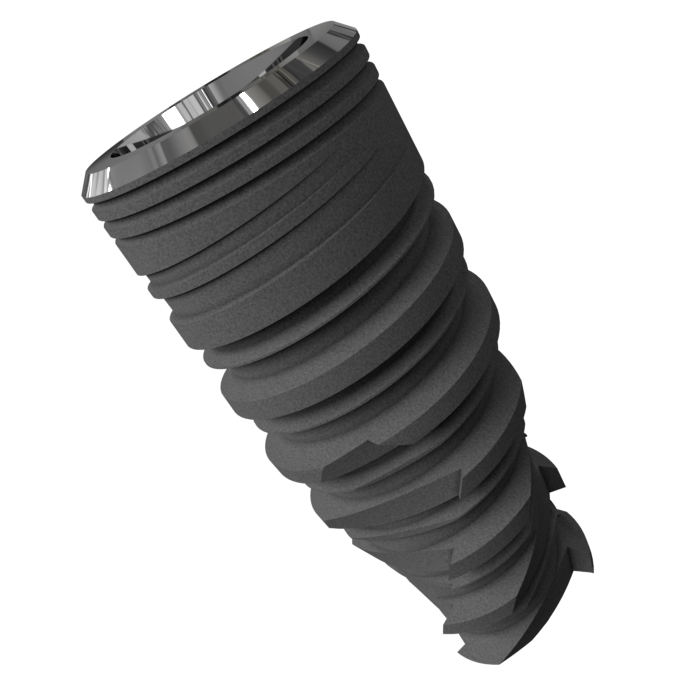

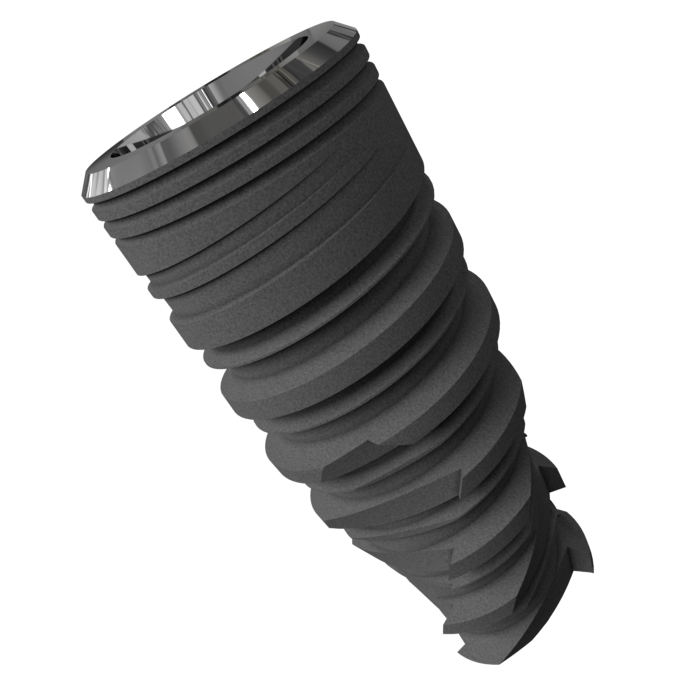

In view of the studies that identify the concentration of mechanical stress in cortical areas as a possible cause of bone resorption, the IML engineers have designed the Universe implant

with an internal geometry that makes it possible for the implant-abutment-screw system to behave like a single one-piece implant system. Indeed, the Universe implant-abutment-screw connection has a total height up to about 5.5 mm.

The benefit of this is better distribution of the load and the levers, which spread 80% of the force throughout the system instead of only centring them on the cortical area as is frequently the case in other implant systems.

|

|

QUALITY |

| Laboratory | Clinic | Studio | Other |

|

I have read, understood and agree to the terms of the privacy policy |

SEND

|

|