01

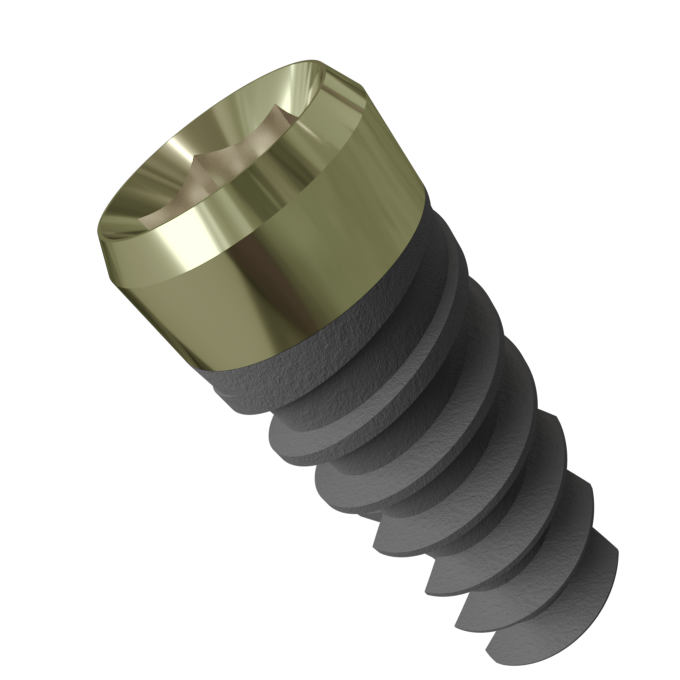

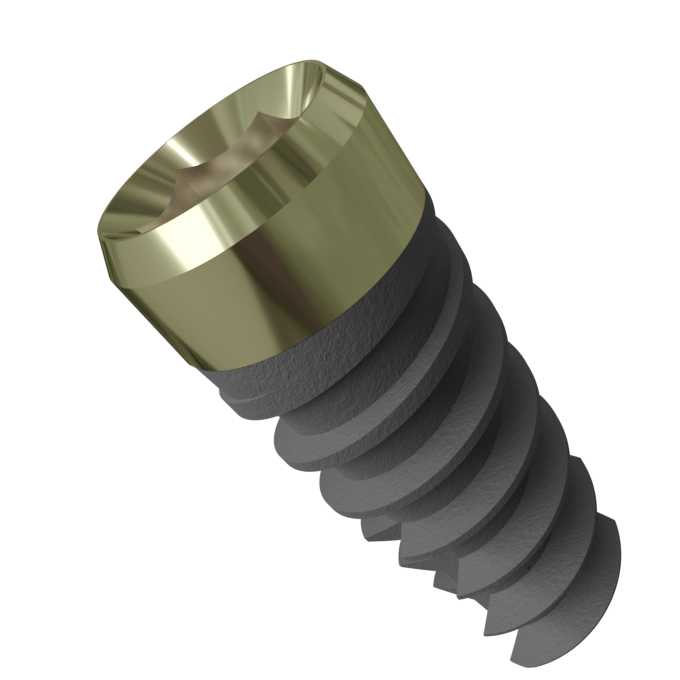

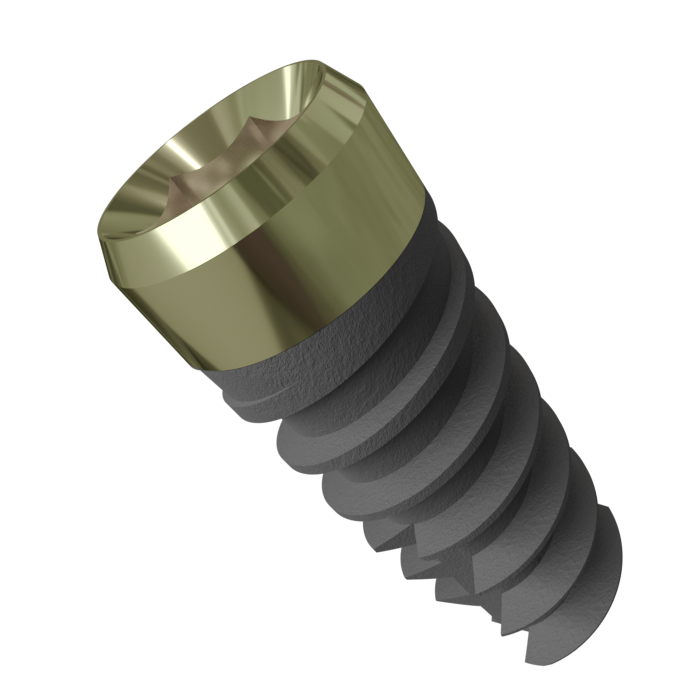

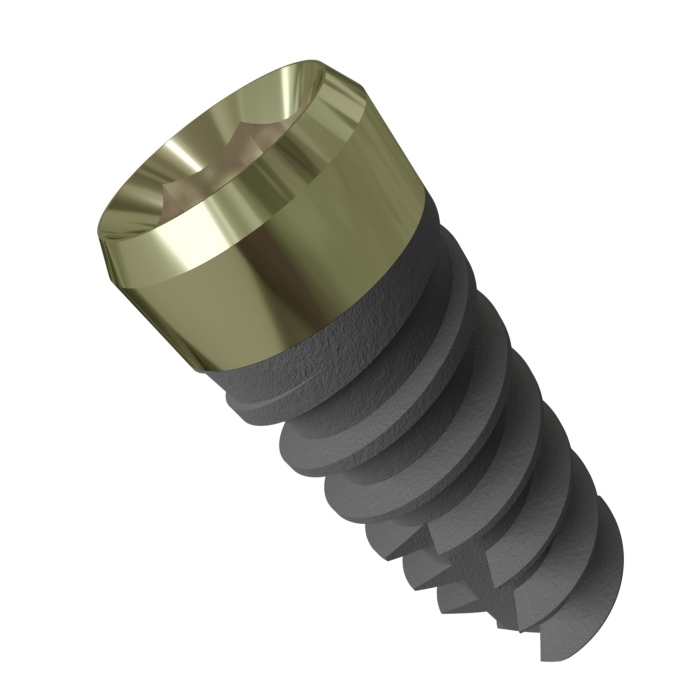

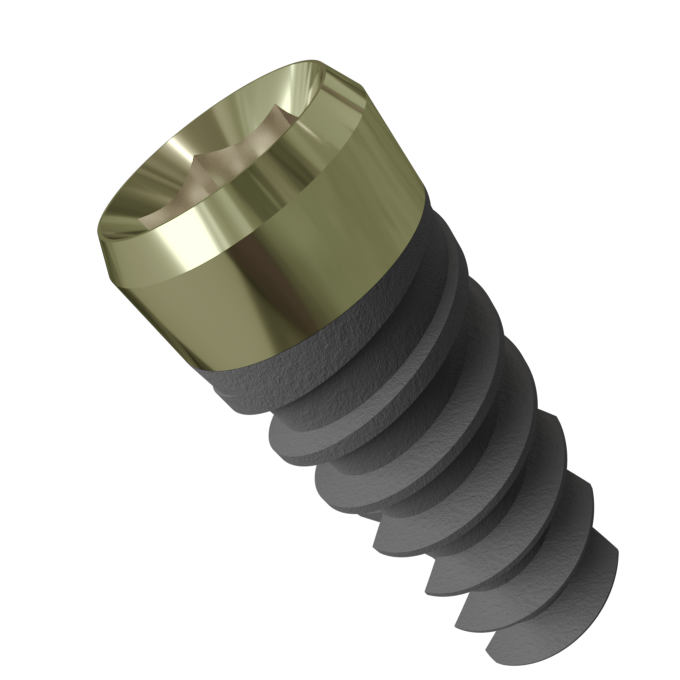

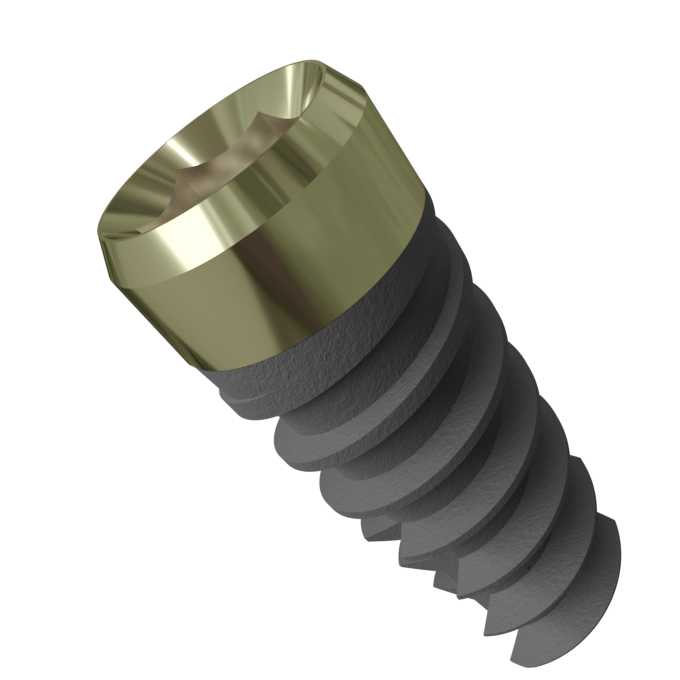

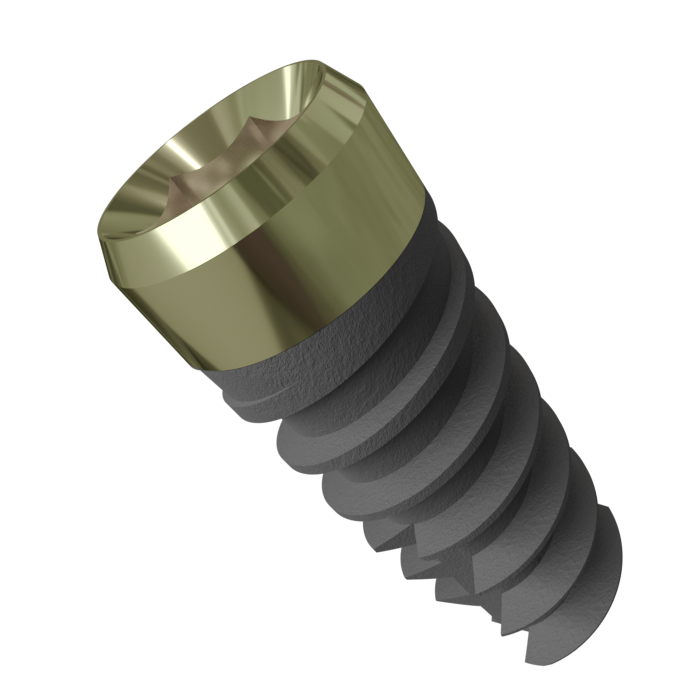

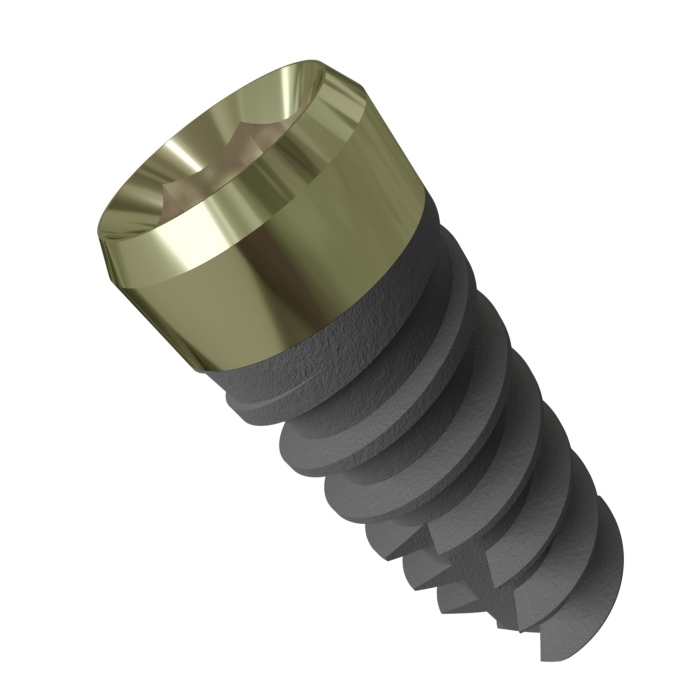

STARFLY |

01

The perfect solution for:

|

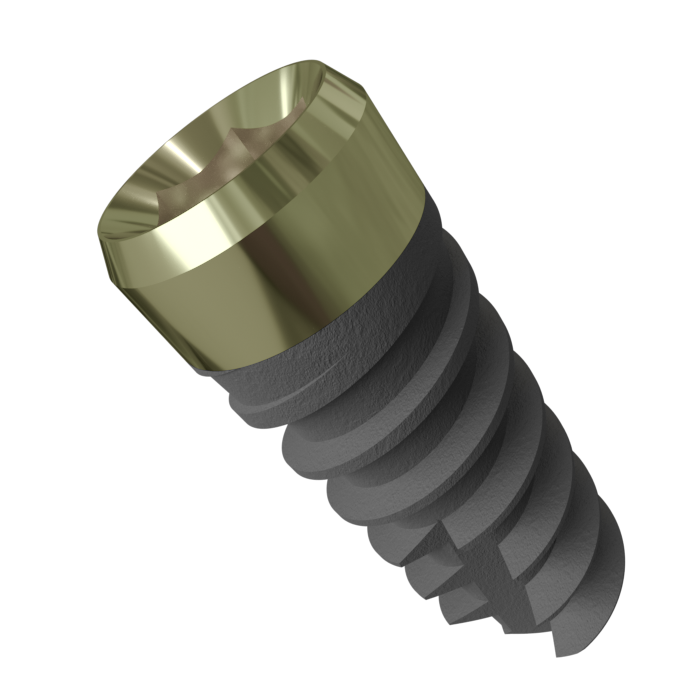

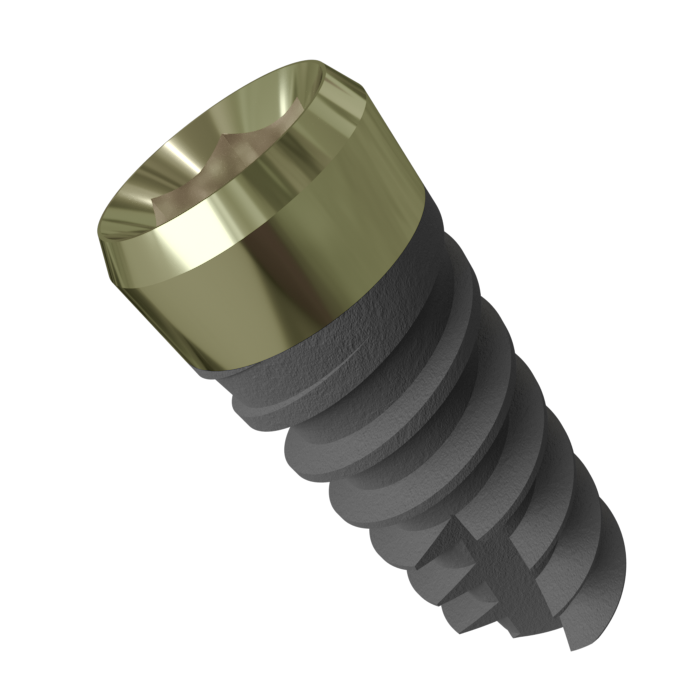

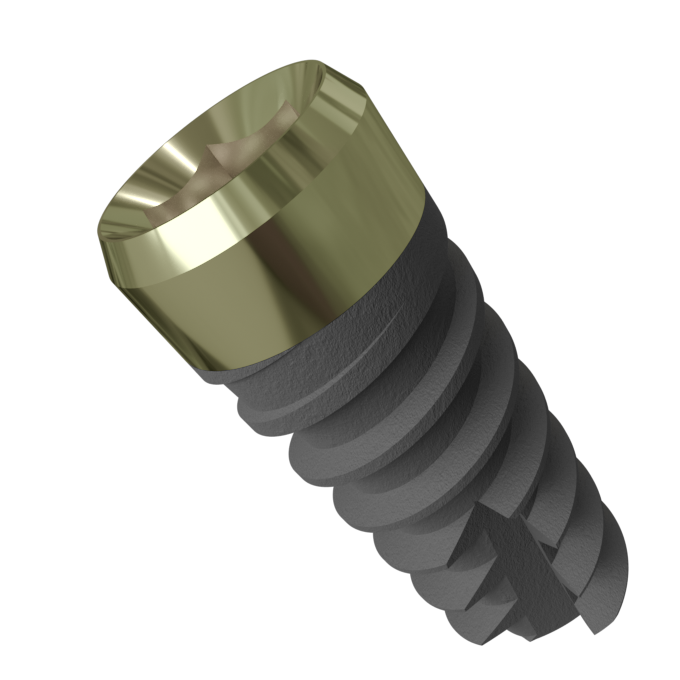

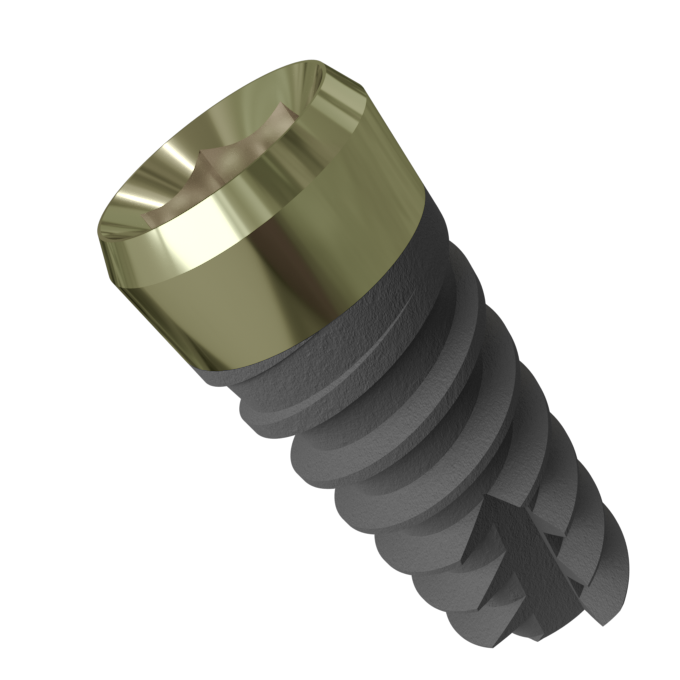

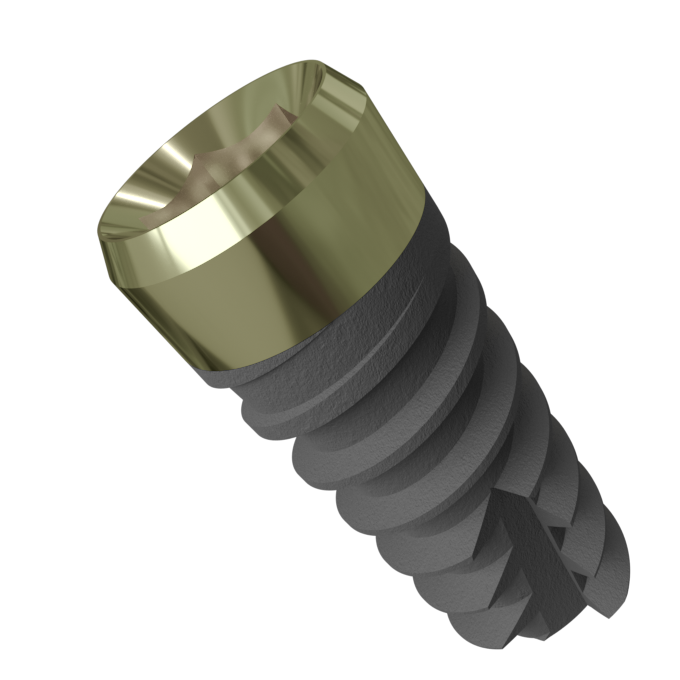

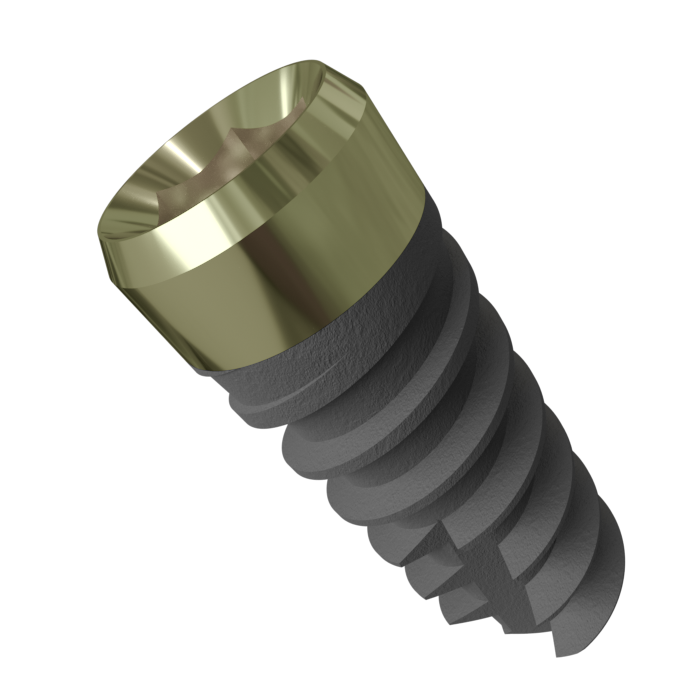

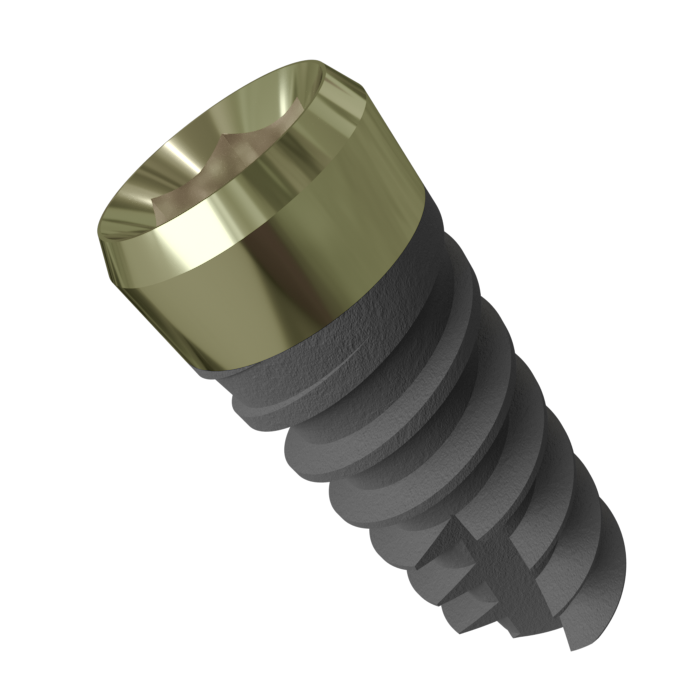

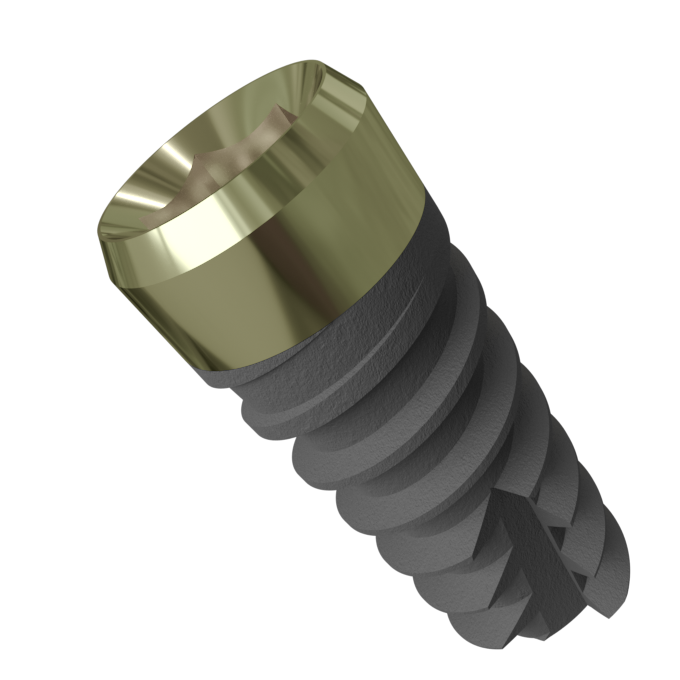

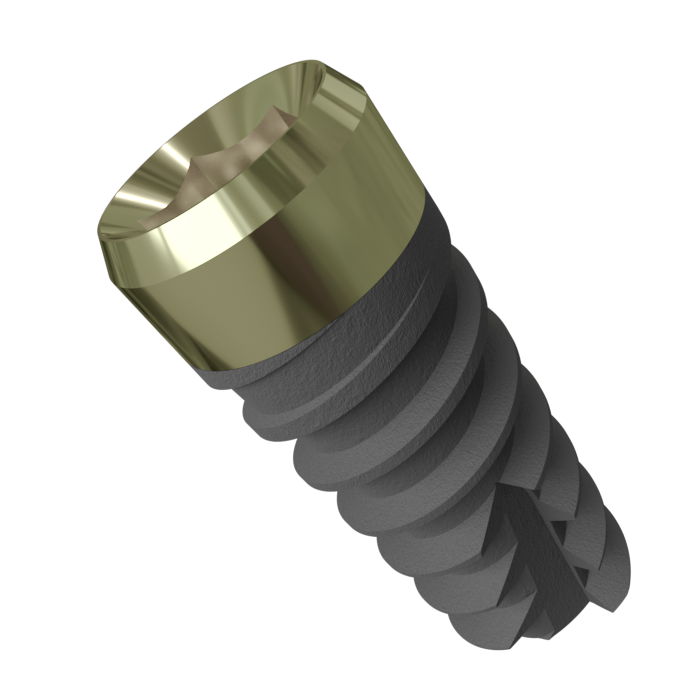

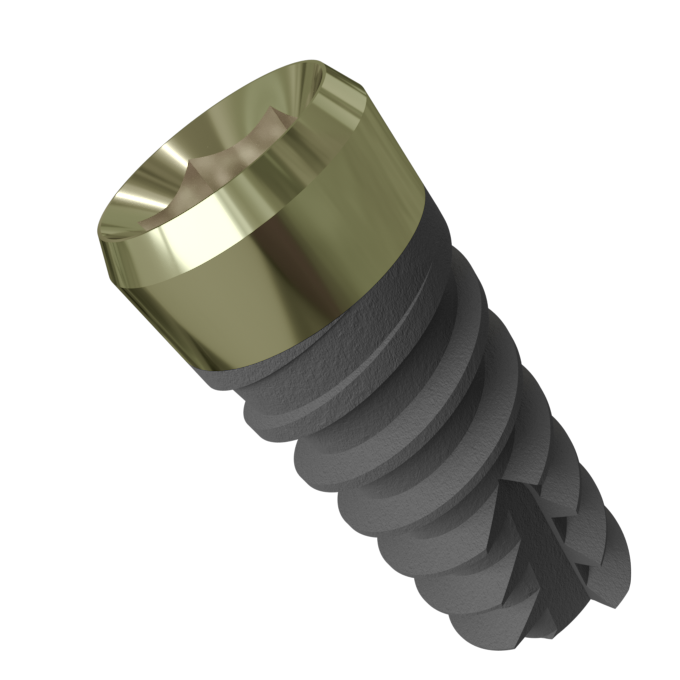

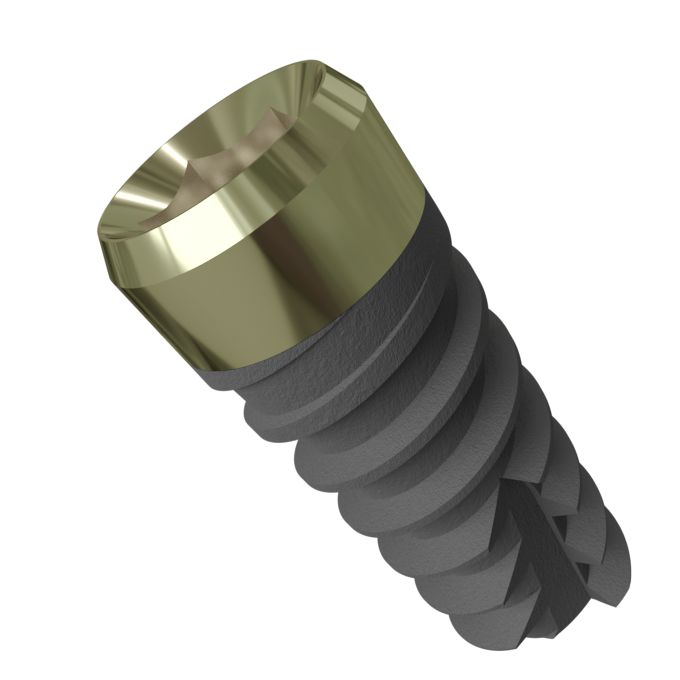

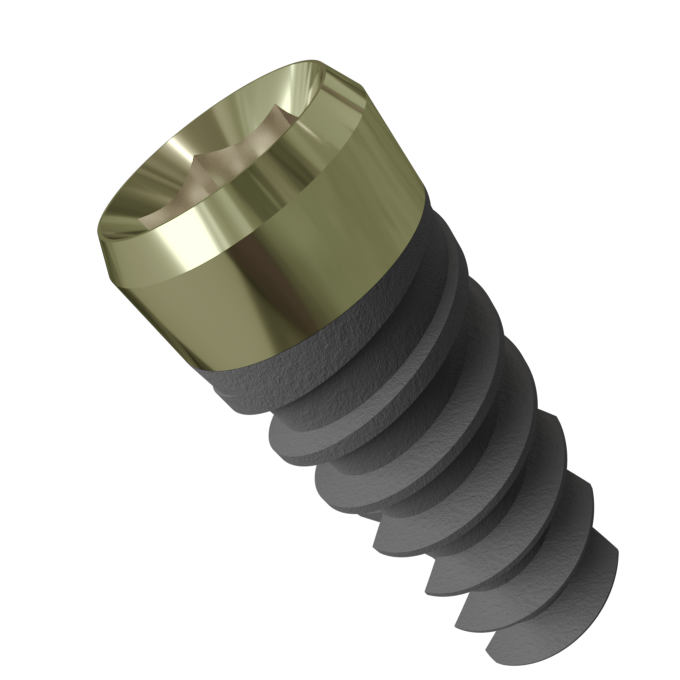

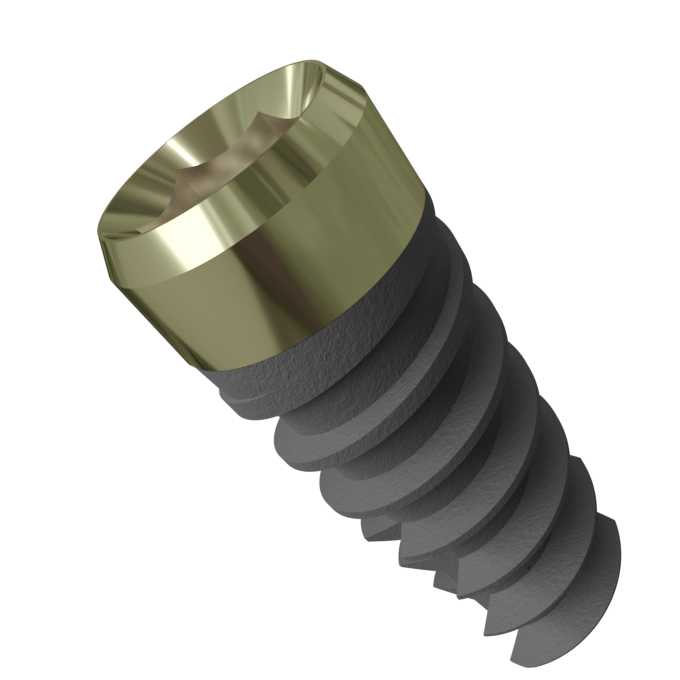

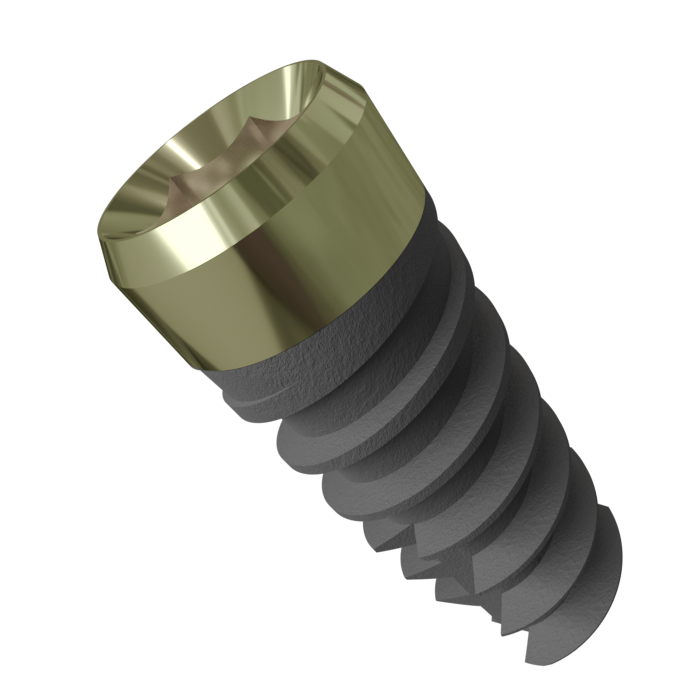

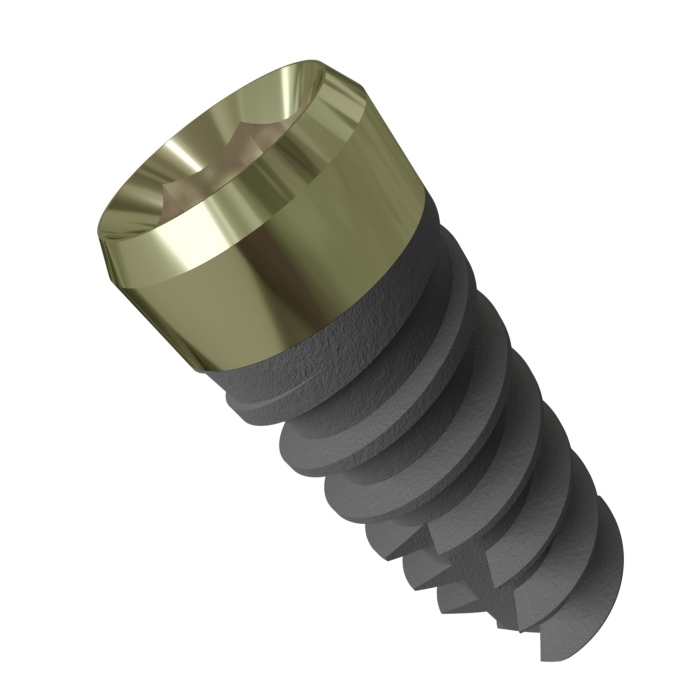

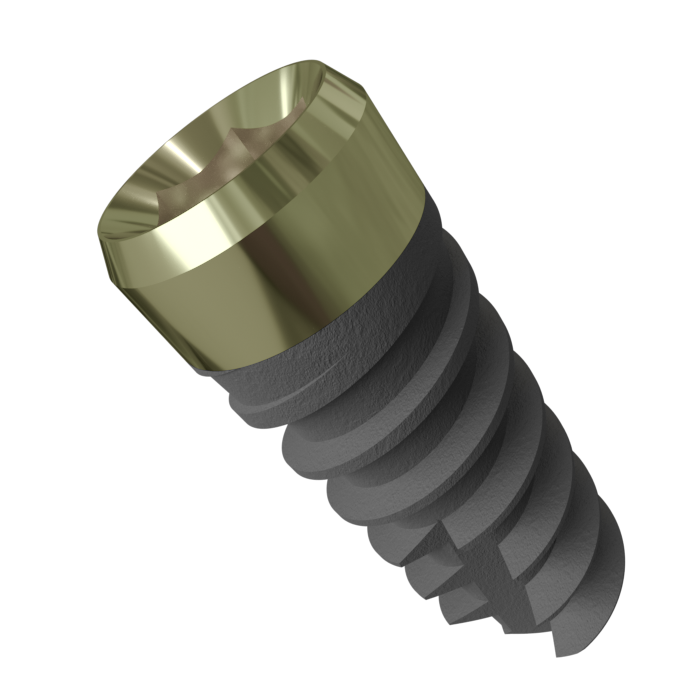

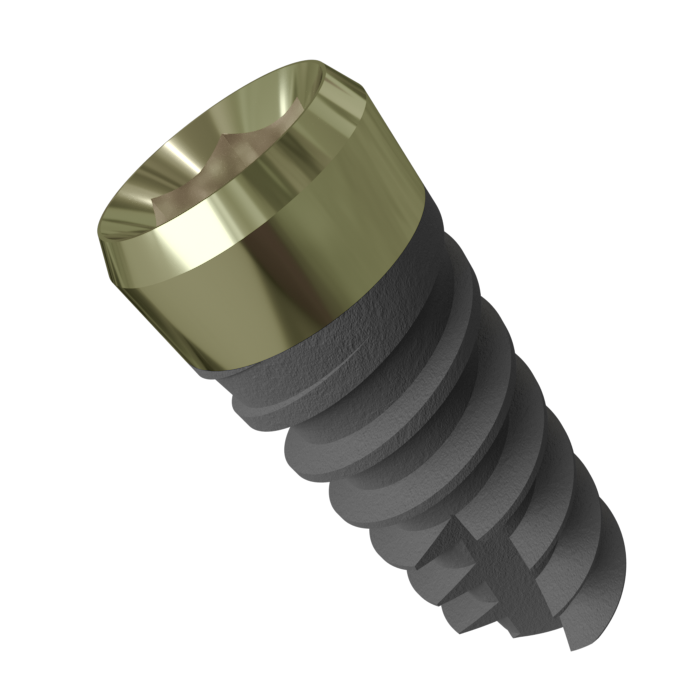

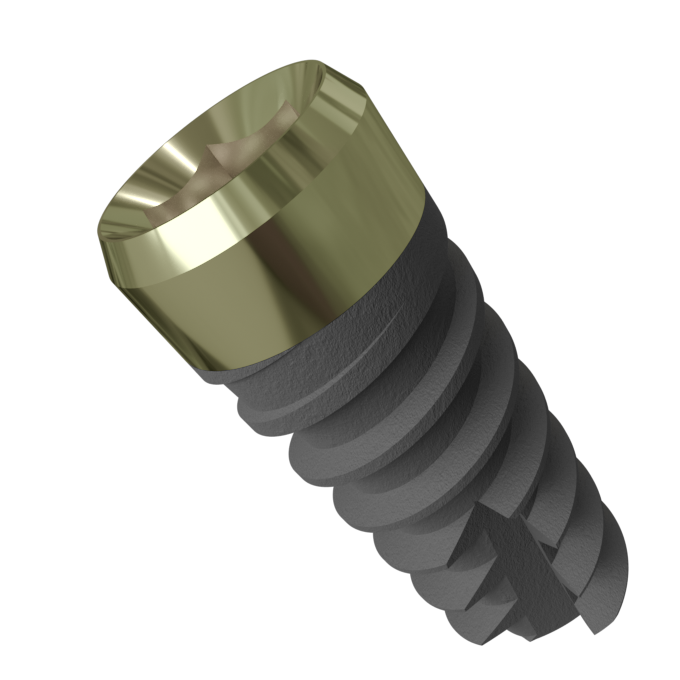

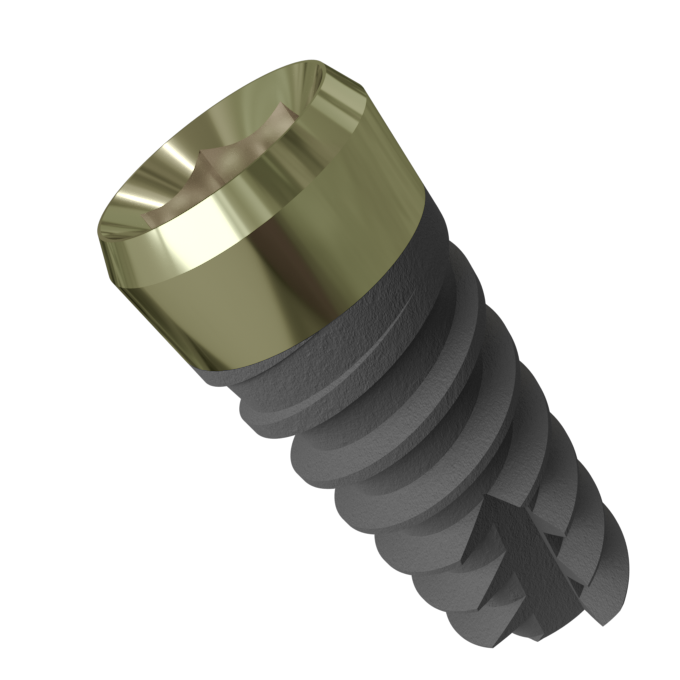

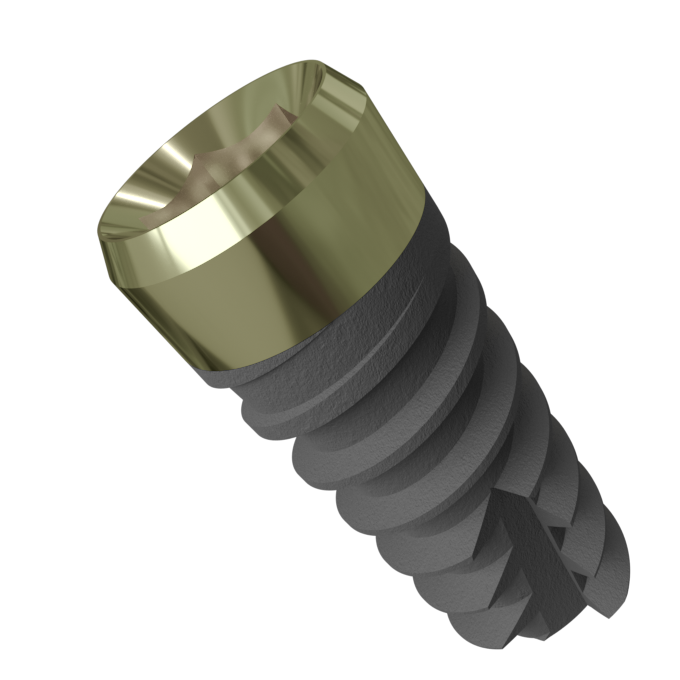

The design of the Starfly implant guarantees high performance in conditions of low bone density.

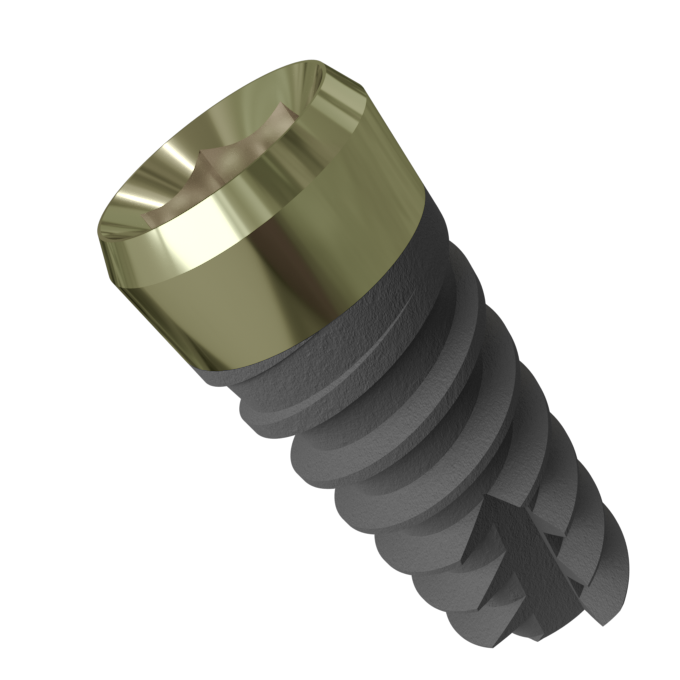

The insertion of the implant is particularly simple in medium and soft bone (D2/D4) and in post-extraction cases, with a reduced osteotomy and guaranteeing excellent primary stability in any case.

In fact, in D3/D4 type bone, the drilling depth can be even lower than the implant length, since the Starfly implant is capable of “making its way” into the bone, up to completely submerge the SL treated part and the polished neck 1,5 mm h.

In case of positioning of the implant in D1 dense bone, the osteotomy must correspond to the implant length and the alveolus must be appropriately prepared by the specific countersink.

The rounded tip facilitates the centering of the implant hole and reduces the lesions risk to anatomical structures, such as mandibular nerve, maxillary sinus and blood vessels.

Below, an example of surgical protocol for the

preparation of an implant site in dense bone.

Respecting the peculiar differences between the bone tissue and soft tissues, the Starfly implant is hybrid, with different surface treatments depending on the portion.

Towards the cortical portion, the SL treated spirals end in a polished cylindrical neck 1.5 mm h, aimed at the endo-osseous positioning. The smooth neck surface contrasts the bacterial attack and its proliferation over time, reducing the risk of peri-implantitis and bone resorption.

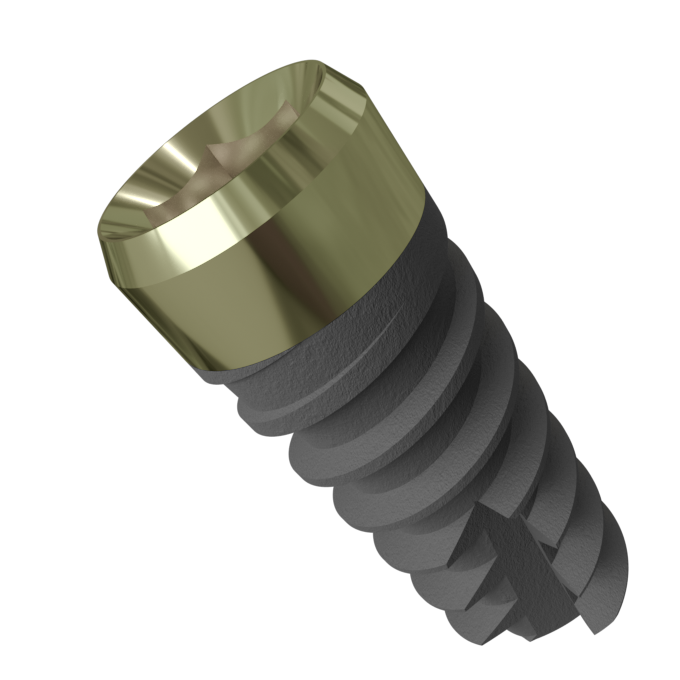

Then, the cylindrical and polished part tapers up to the 3.5 diameter, resulting in a golden-yellow anodized switching platform, which enhances the soft tissues adhesion and, in the meantime, contrasts the bacterial colonization attack.

The Starfly implant has only one platform size connecting to the prosthetic components, regardless the implant diameter. It is Ø 3.5 mm and called RP (regular platform). The golden-yellow anodized switching platform, 0.5 mm high, links up the different implant diameters to the single diameter of prosthetic components.

Therefore the switching platform tapering is more evident in implants with larger diameter. For the Ø 3.5 implant, instead, the diameter of the implant coincides with the diameter of the platform; so, in this case, the switching platform shows a cylindrical morphology, not tapered.

The combination of all these features guarantees

flexibility in managing the depth during the implant positioning, without

altering the primary stability of the implant, even in medium / soft bone.

The

Starfly implant shows a flaring internal hexagonal connection. This kind of

connection, combined with Friction abutments and manufactured in compliance

with the excellence standards that distinguish the entire IML production

process, reduces the horizontal strain on the bone, distributes correctly the

masticatory forces within the implant, protects the retention screw from

excessive load, guarantees an excellent stability of the prosthetic parts and

an optimal, long-lasting bacterial seal.

The essential conditions to implement such excellent performances are the perfectly centered internal hexagon in relation to the implant axis and the tolerance of 5 thousandths of a mm on the hexagon measure, guaranteed on 100% of the production.

Starfly prosthetic parts too are manufactured in strict compliance with measures and tolerances.

In fact, IML applies the same high-quality

standards during the production of each component, not only for the implants.

In this way, IML mechanically achieves the perfect coupling between implant and

abutment.

|

|

QUALITY |

| Laboratory | Clinic | Studio | Other |

|

I have read, understood and agree to the terms of the privacy policy |

SEND

|

|